50/10t吊钩桥式起重机小车机构设计

无需注册登录,支付后按照提示操作即可获取该资料.

50/10t吊钩桥式起重机小车机构设计(论文说明书12000字,cad图纸6张)

摘 要:设计采用许用应力法以及计算机辅助设计方法对桥式起重机桥架金属结构进行设计。设计过程先用估计的桥式起重机各结构尺寸数据对起重机的强度、疲劳强度、稳定性、刚度进行粗略的校核计算,待以上因素都达到材料的许用要求后,画出桥架结构图。然后计算出主梁和端梁的自重载荷,再用此载荷进行桥架强度和刚度的精确校核计算。若未通过,再重复上述步骤,直到通过。由于桥架的初校是在草稿中列出,在设计说明书中不予记录,仅记载桥架的精校过程。设计中参考了各种资料, 运用各种途径, 努力利用各种条件来完成此次设计. 本设计通过反复斟酌各种设计方案, 认真讨论, 不断反复校核, 力求设计合理;通过采取计算机辅助设计方法以及参考前人的先进经验, 力求有所创新;通过计算机辅助设计方法, 绘图和设计计算都充分发挥计算机的强大辅助功能, 力求设计高效。

关键词:桥式起重机; 机构设计

Design of Crane Car Organizaation of 50/10T Bridge-type Hoist

Abstract:Designed using allowable stress method, and computer-aided design of metal structures of bridge crane bridge design. Design first with the estimated size of the data bridge crane on the crane structure, strength, fatigue strength, stability, rigidity for rough checking calculation, these factors have to be allowable to the material requirements, draw bridge structure . Then calculate the main beam and side beam weight load, and then load the bridge this exact strength and stiffness of checking calculation. If not passed, then repeat the above steps until approved. Since the beginning of the school is the bridge is listed in the draft, no record in the design manual, only the essence of the school record the process of bridge. Reference to the design of various types of information, using various means, to use a variety of conditions to complete the design. By the design, various designs, and repeated discussion on the nuclear and try to design and reasonable. through a computer-aided design and the advanced experience of reference for innovation; used in computer-aided design, graphics and design calculations are full of accessibility, the computer efficiently. to design

Key Words: bridge crane; institutions designed

目 录

摘要------------------------------------------------------------------------------------------------1

关键词---------------------------------------------------------------------------------------------1

1 前言---------------------------------------------------------------------------------------------2

2 国内外研究现状------------------------------------------------------------------------------4

3 小车主起升机构设计------------------------------------------------------------------------5

3.1 确定传动方案-------------------------------------------------------------------------5

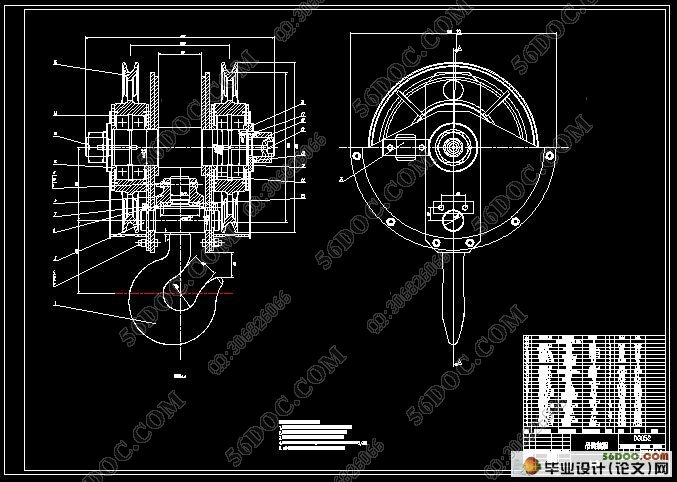

3.2选择滑轮组和吊钩组-----------------------------------------------------------------5

3.3初选电动机-----------------------------------------------------------------------------5

3.4选用标准减速器-----------------------------------------------------------------------6

3.5校核减速器输出轴强度--------------------------------------------------------------6

3.6电动机过载验算和发热验算------------------------------------------------------7

3.7选择制动器---------------------------------------------------------------------------7

3.8选择联轴器---------------------------------------------------------------------------8

3.9选择钢丝绳---------------------------------------------------------------------------8

3.10确定卷筒尺寸并验算强度--------------------------------------------------------10

3.11验算起动时间-----------------------------------------------------------------------10

3.12验算制动时间-----------------------------------------------------------------------11

3.13 高速轴设计-------------------------------------------------------------------------12

4 小车副起升机构设计----------------------------------------------------------------------13

4.1 确定传动方案 ---------------------------------------------------------------------13

4.2选择滑轮组和吊钩组--------------------------------------------------------------14

4.3初选电动机--------------------------------------------------------------------------14

4.4选用标准减速器--------------------------------------------------------------------14

4.5校核减速器输出轴强度-----------------------------------------------------------15

4.6电动机过载验算和发热验算-----------------------------------------------------15

4.7选择制动器--------------------------------------------------------------------------16

4.8选择联轴器--------------------------------------------------------------------------17

4.9钢丝绳的选择------------------------------------------------------------------------17

4.10确定卷筒尺寸并验算强度--------------------------------------------------------18

4.11验算起动时间-----------------------------------------------------------------------19

4.12验算制动时间-----------------------------------------------------------------------19

4.13 高速轴设计-------------------------------------------------------------------------20

5.小车运行机构设计-----------------------------------------------------------------------------------22

5.1 确定机构传动方案-----------------------------------------------------------------22

5.2 选择车轮与轨道并验算其强度--------------------------------------------------22

5.3 运行阻力计算 ----------------------------------------------------------------------23

5.4 选电动机-----------------------------------------------------------------------------24

5.5 验算电动机发热条件--------------------------------------------------------------25

5.6 选择减速器--------------------------------------------------------------------------25

5.7 验算运行速度和实际所需功率--------------------------------------------------25

5.8 验算起动条件-----------------------------------------------------------------------25

5.9 按起动工况校核减速器功率-----------------------------------------------------26

5.10 验算起动不打滑条件-------------------------------------------------------------27

5.11 选择制动器-------------------------------------------------------------------------28

5.12 选择联轴器-------------------------------------------------------------------------28

5.13 验算低速浮动轴的强度----------------------------------------------------------29

5.14 小车缓冲器-------------------------------------------------------------------------30

结论-----------------------------------------------------------------------------------------------------------32

参考文献---------------------------------------------------------------------------------------------------33

致谢--------------------------------------------------------------------------------------------34