4.7吋苹果6(iPhone6)保护套的注塑模具设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

4.7吋苹果6(iPhone6)保护套的注塑模具设计(含CAD零件装配图)(设计说明书13500字,CAD图纸13张)

摘 要

塑料工业是当今世界上曾长最快的工业门类之一,而注塑模具是其中发展较快的种类,因此,研究注塑模具对了解注塑产品的生产过程,提高产品质量和降低产品成本都具有重大意义。

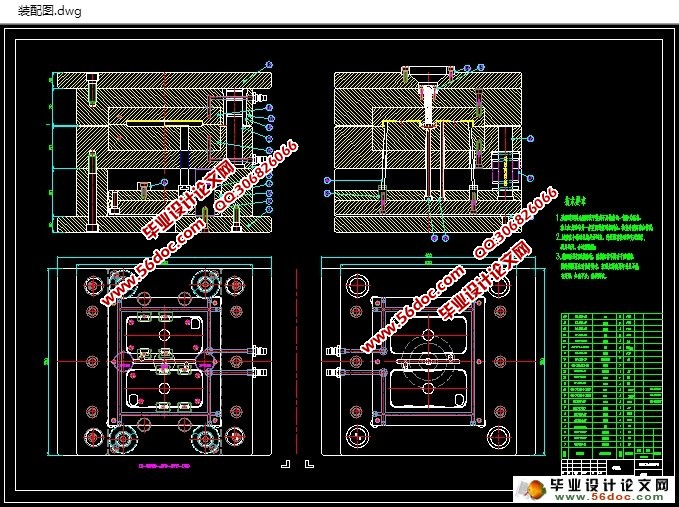

本设计为手机壳注塑模具设计,它介绍了注塑成型的基本原理,系统的阐明塑料件模具中的各个零部件的加工工艺过程及整套模具的装配和使用。其中,涉及到注射机各种参数的选取、零部件的加工方法、注射模的结构及相关的计算问题及特种加工工艺。详细介绍了冷流道注塑模具浇注系统、温度控制、定出装置设计过程。在该模具设计中,充分利用计算机绘图软件绘制了零件图和装配图,对模具参数进行了设计。

塑料的种类很多,其成形的方法也很多,有注射成形、压缩成形、压注成形、挤出成形、气动与液压成形、泡沫塑料的成形等,其中前四种方法最为常用。其中,注射成形所用模具称为注射成形模具,简称注射模。注射模主要应用于成形热塑性塑料,因此根据对零件的分析,该PC材料的塑料手机壳用注射成形为最佳。另外,注射模区别于其他塑料模的特点是:模具先由注射机合模机构合紧密,然后,由注射机注射装置将高温高压的塑料熔体注入模腔内,经冷却或固化定型后,开模取出塑件。因此,注射模可一次成形出外形复杂、尺寸精确或带有嵌件的塑料制件,对手机壳的外观有精美、无明显毛刺等要求的情况下,应用注射成形可以很好的达到工艺要求。

塑料,重量轻,抗逆性强,耐化学性,电绝缘性好,价格便宜,可塑性好等特点,广泛应用于电脑,手机,汽车,电器,电子,家电和通讯产品制造可延展的合成高分子材料。注塑是被注入到在模具中获得的产物冷却固化的塑造件是指在高压下的热塑性熔融物利用注塑成型机的主要方法之一。注射成型的优点是生产的高速,高效率运转,可以自动的,它可以被模制复杂的形状,特别适合于大批量生产的部件。这个毕业设计的产品为手机外壳,重量轻,强度高,耐腐蚀,易清洁,为大规模生产的产品。分析产品来确定模具分型面,型腔数目,浇口形式,位置大小之后的设计过程;最重要的是确定芯和腔体的结构,以及它们的定位和固定的方式。此外,它进行了设计,模具设计导向机构,冷却系统释放机制的设计。最后,绘制一个卡的制造加工过程完成模具组件的总图和模具的主要部分和模制零件的制剂。实践证明:模具结构合理,可靠,并能保证产品的质量,这样的产品的注塑模具设计具有参考值。

关键词: 塑料; 注塑成形; 模具设计

Abstract

Plastic industry is one of the world today has been the fastest growing industrial categories, and injection mould is one of the types of rapid development. Therefore, on injection mold injection molding products to the understanding of the production process, improve product quality and reduce the cost of products is of great significance.

The design for mobile phone shell injection mold design, it introduces the basic principle of injection molding, system to elucidate the assembly and use of the plastic mold parts processing process and a complete set of mould. Which is related to the injection machine parameter selection, parts of the processing methods, and special processing technology of injection mold structure and the related computational problems was introduced in detail. The cold runner injection mold gating system, temperature control, set the device design process. In the design of the mould, make full use of computer drawing software to draw the part drawing and assembly drawing, design of mould parameters.

With the shell of the mobile phone. Known as the lot of many kinds of plastics and its forming method, injection molding, compression molding, injection molding, extrusion forming, pneumatic and hydraulic forming, foam forming, of which the first four method is the most commonly used. The injection forming mold for injection molding mold, referred to as the injection mold injection mold is mainly applied to forming thermoplastic plastic, so according to the parts of the analysis, the PC material of plastic injection molding is the best. In addition, injection mould is different from other plastic mold: mold injection machine mould clamping mechanism together tightly, and then by injection molding machine injection device of high temperature and high pressure plastic melt into the mold cavity , after cooling and solidification. The mould is opened to take out the plastic parts. Therefore, injection mold can be forming a complex shape, size precision or with embedded pieces of plastic parts, the appearance of mobile phone shell is exquisite, no obvious burrs etc. requirements, injection forming can be very good to meet the process requirements.

Plastic is a malleable synthetic polymer material with light weight and strong resistance, chemical resistance, electrical insulation and good, cheap, good plasticity and other characteristics, widely used in computers, mobile phones, automotive, electrical, electronics, home appliances and communications product manufacturing. Injection molding is one of the main methods to shape the piece refers to the use of an injection molding machine under high pressure thermoplastic melt is injected into the product obtained in the mold is cooled to solidify. The advantage of injection molding is the production of high speed, high efficiency operation can be automated, it can be molded parts of complex shape, particularly suitable for mass production. This graduation design products for phone case, light weight, high strength, corrosion-resistant, easy to clean, for the mass production products. The design process after analysis for the product to determine the mold parting surface, cavity number, gate form, position size; the most important is to determine the structure of the core and cavity, as well as their positioning and fastening the way. Also it carried out design, mold design guide mechanism, design of the cooling system release mechanism. Finally, draw a card manufacturing machining process complete mold assembly general diagram and the main parts of the mold and the preparation of molded parts in FIG. Practice has proved that: the mold structure is reasonable, reliable, and to ensure product quality, injection mold design of such products with a reference value.

Keywords: Plastic; Injection molding; Mold design

目 录

第一章 前言 1

1.1 模具在加工工业中的地位 1

1.2 模具的发展趋势 2

1.3 设计在学习模具制造中的作用 3

第二章 塑料的工艺分析 4

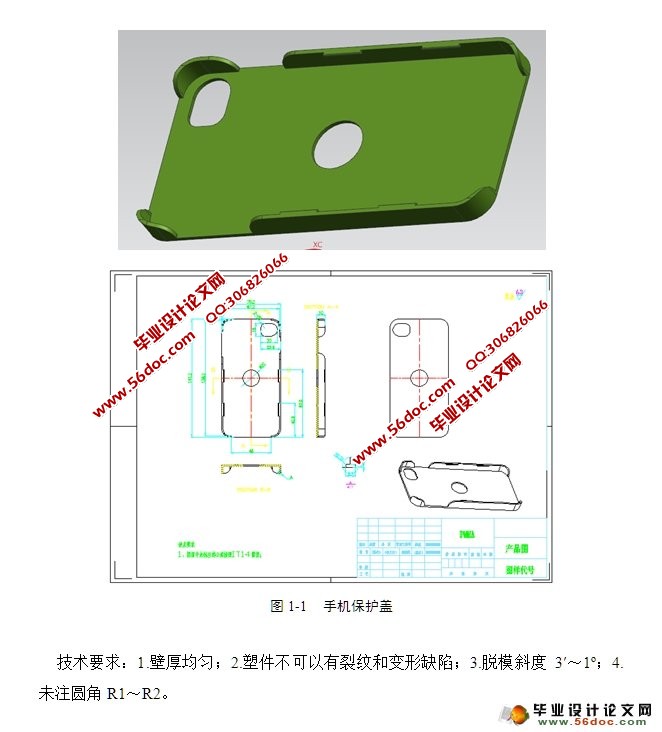

2.1 塑件元件图及技术要求 4

2.2 原料(ABS)的成型特性和工艺参数 5

2.2.1 ABS塑料主要的性能指标 5

2.2.2 ABS的注射成型工艺参数 5

第三章 注塑设备的选择 7

3.1 注射成型工艺条件 7

3.1.1 模具所需塑料熔体注射量 7

3.1.2 分型面上的投影面积及所需锁模力 7

3.2 选择注射机 8

3.3 模架的选定 8

3.4 注射机的校核 8

3.4.1 最大注射量的校核 8

3.4.2 锁模力校核 9

3.4.3 模具与注射机安装部分相关尺寸校核 9

第四章 型腔布局与分型面设计 11

4.1 型腔的布局 11

4.2 分型面的设计 11

第五章 浇注系统的设计 13

5.1 主流道的设计 13

5.2 主流道衬套的设计 14

5.3 分流道的设计 14

5.4 浇口的选择 16

5.4.1 浇口的选用 16

5.4.2 浇口位置的选用 16

5.4.3 浇注系统的平衡 17

5.4.4 排气的设计 17

第六章 成型零件的设计 18

6.1 成型零件的结构设计 18

6.1.1 凹模结构设计 18

6.2 成型零件工作尺寸计算 19

6.2.1 外形尺寸 20

第七章 合模导向机构的设计 21

7.1 导柱结构 22

7.2 导套结构 22

7.3 侧抽芯机构的设计 22

7.3.1 抽拔力 22

7.3.2 抽芯距 23

第八章 脱模机构的设计 24

8.1 脱模机构设计的总原则 24

8.2 推杆设计 24

8.2.1 推杆的形状 24

8.2.2 推杆的位置和布局 24

第九章 温度调节系统的设计 26

9.1 模具冷却系统的设计 27

9.2 模具加热系统的设计 27

第十章 模具的装配 28

10.1 模具的装配顺序 28

10.2 开模过程分析 29

参考文献 30

致谢 31