瓶盖注塑模设计(含cad零件图和装配图,工艺卡)

无需注册登录,支付后按照提示操作即可获取该资料.

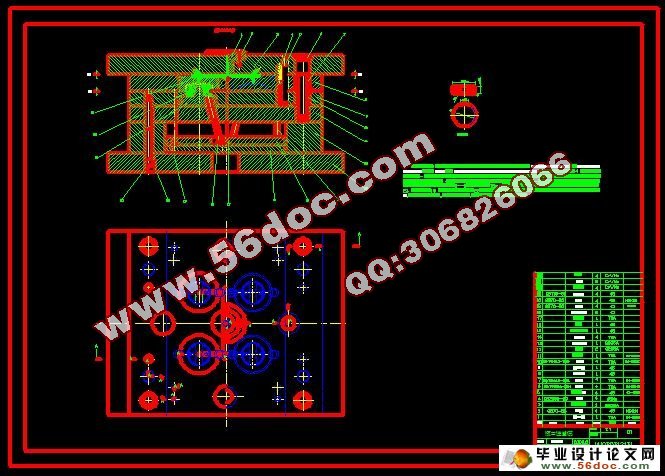

瓶盖注塑模设计(含cad零件图和装配图,工艺卡)(任务书,开题报告,中期检查,工艺卡,设计说明书11000字,CAD图纸9张)

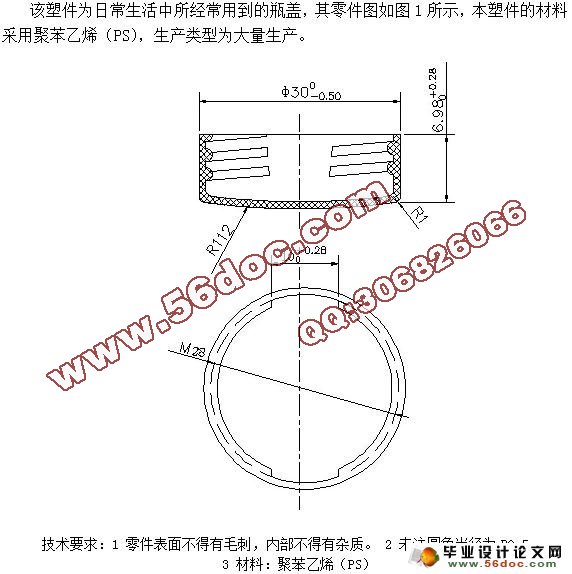

摘要:通过分析间断型内螺纹瓶盖的工艺性,可知内螺纹为半圆型螺纹,由于该瓶盖的材料为聚苯乙烯(PS),该材料不宜采用强制脱模。所以塑件采用内抽芯机构进行脱模,由图可知,内螺纹为两个局部段,对应在模具上制成两个内抽的滑块。当动定模分型时,在连接推杆的作用下,八个成型螺纹滑块沿T形槽移出,产生向心的收拢运动。这些滑块始终不脱离型芯座。由于瓶盖的上部分要求严格,所以采用点浇口浇注系统,脱模后不在修正浇口的痕迹。但采用这种浇口时,常常要在模具上增加一个分型面,以便浇口凝料脱模。

关键词:螺纹滑块 内抽芯 点浇口

Abstract:Pass the analysis interrupteds the craft of a cover of thread inside the type, can know is a thread of semicircle inside the thread, because of in order to gather the styrene( PS), that bottle of material for cover that material should not adopt to take off the mold compulsory.So an adoption ofinside take out the organization ofto carry on taking off the mold, can know from the diagram, inside the thread is two partial segment, in molding tool ascend make into twoth to should take out of slippery piece.When move to settle the type of cent of mold, while link the function of push the pole, eight model the thread the slippery piece follows the T form slot to move, producing to accept the sport of centripetally.These slippery pieces do not escape from a always.Because the upper part of a cover requests separately strictly, so the adoption orders to sprinkle to sprinkle to note the system, after taking off the mold not sprinkle the oscular trace in the correction.But adopt this kind of to sprinkle, usually want to increase the type of a cent to face on the molding tool, in order to sprinkle a peopleto anticipate to take off the mold.

Keyword:Slippery piece of thread Inside take out Order to sprinkle

目录

绪论………………………………………………………………………1

第1章 模塑工艺规程的编程…………………………………………………3

1.1 塑件的工艺性分析……………………………………………………… 3

1.2 计算塑件的体积和重量………………………………………………… 4

1.3 塑件注塑工艺参数的确定……………………………………………… 5

第2章 注塑模的结构设计……………………………………………………6

2.1 分型面选择……………………………………………………………… 6

2.2 确定型腔的排列方式…………………………………………………… 7

2.3 浇注系统设计…………………………………………………………… 8

2.4 导柱和导套的选择………………………………………………………10

2.5 抽芯机构设计……………………………………………………………11

2.6 排气系统的设计…………………………………………………………12

2.7 成型零件结构设计………………………………………………………12

第3章 模具设计的有关计算……………………………………………… 15

3.1 型腔和型芯工作尺寸计算…………………………………………… 15

3.2 凹模型腔尺寸的计算………………………………………………… 15

第4章 模具加热与冷却系统的计算……………………………………… 16

第5章 模具闭合高度的确定……………………………………………… 18

第6章 注塑机有关参数的校核…………………………………………… 19

第7章 绘制模具的总装图和非标零件工作图………………………… 20

第8章 注塑模具的安装和试模…………………………………………… 21

结论…………………………………………………………………… 24

致谢…………………………………………………………………… 25

参考文献………………………………………………………………26