棉花打包机的设计(含CAD零件装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

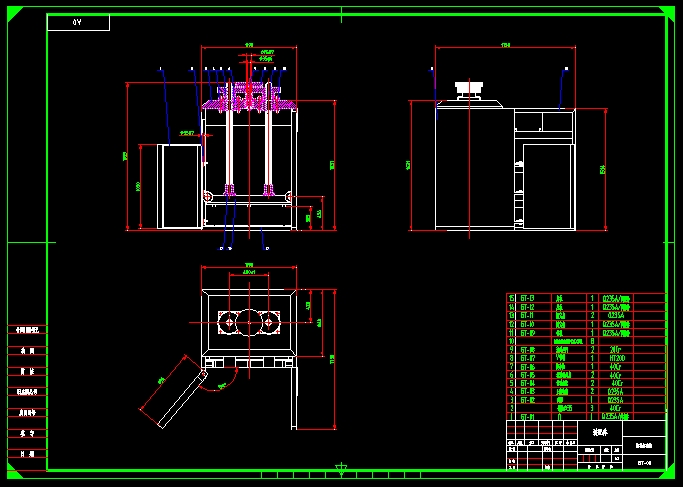

棉花打包机的设计(含CAD零件装配图,SolidWorks三维图)(论文说明书7500字,CAD图纸9张,SolidWorks三维图)

Design of cotton packing machine

摘要

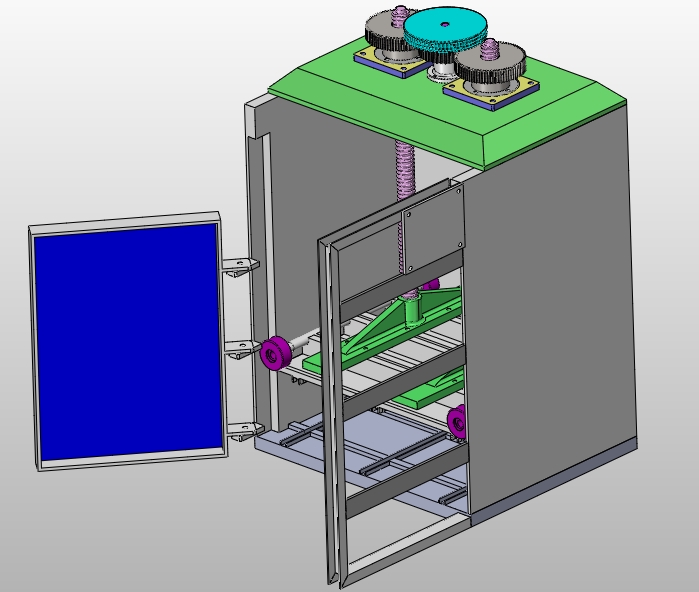

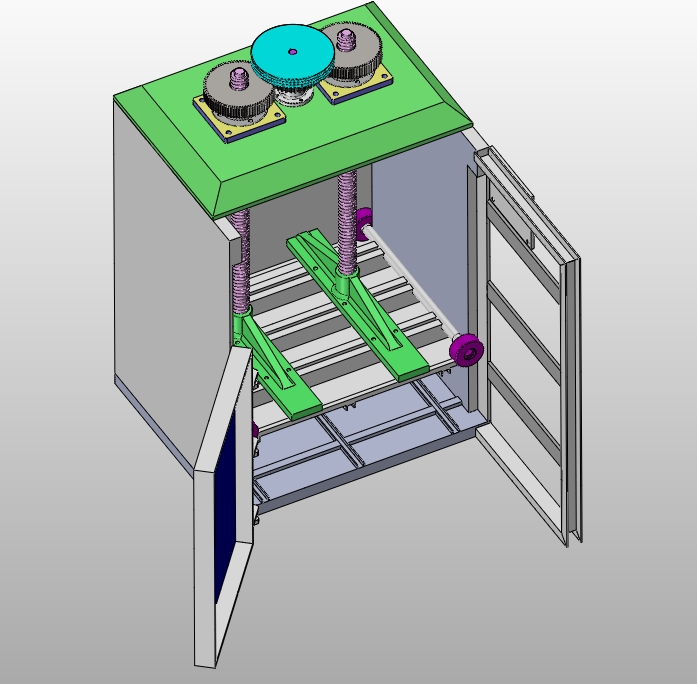

本次设计的题目是棉花打包机的设计,棉花打包机它具有结构新颖、技术含量高、刚性和稳定性好、自动化程度高、造型美观、节能等特点。本机为上顶式,所以棉花无污染,采用V带传动通过齿轮传动从而带动滚珠丝杆转动,滚珠丝杆的升降从而带动压棉板的升降,从而来进行棉花的压缩,打包,该机是机、电一体化产品的典型代表。

传统的实现棉花打包的方法都是依靠人工的方式,工作效率低下,与此同时,打包质量也得不到保证,而本课题所设计的棉花打包机,能够实现棉花的自动打包,在人工打包的基础上面大大地提高了生产效率,降低了劳动成本,特别与发达国家的棉花打包设备相比,还是有一定的差距,因此本次棉花打包机的设计具有重要意义。

关键词:棉花打包机,传动,效率,设计

ABSTRACT

The topic of this design is the design of cotton packing machine. It has the characteristics of novel structure, high technology content, good rigidity and stability, high degree of automation, beautiful appearance, energy saving and so on. The machine is on top, so cotton without pollution, the V belt transmission through the transmission gear to drive the ball screw rod to rotate, the lifting of the ball screw so as to drive the pressing cotton plate movements, so as to carry out cotton compressed, packaged, the machine is mechanical, electrical integration products typical and representative.

Traditional cotton packing method is by means of artificial, work efficiency is low. At the same time, packing quality also can not be guaranteed, but this topic design of cotton balers, cotton can be achieved automatic packaging, in artificial package based on greatly provided high production efficiency, reduce the labor cost, especially with the developed countries of the cotton packing equipment, or have a certain gap, so the cotton packing machine design has important significance.

Key words: Cotton packing machine, transmission, efficiency, design

目 录

摘要 I

ABSTRACT II

1引言 1

1.1课题的来源与研究的目的和意义 1

1.2本课题研究的内容 2

2棉花打包机总体方案的设计 3

2.1棉花打包机的工作原理 9

2.2机械传动部分的设计计算 11

2.2.1电机的选型计算 13

2.2.2 V带传动的设计计算 14

2.2.3滚珠丝杆的设计计算 16

2.2.4齿轮传动的设计计算 18

2.2.5平键的选型计算 18

3棉花打包机中主要零件的三维建模 19

3.1滚珠丝杆的三维建模 22

3.2固定座的三维建模 24

3.3齿轮的三维建模 25

3.4棉花打包机的三维建模 26

4各主要零部件强度的校核 27

4.1机架强度的校核与计算 28

4.2齿轮强度的校核计算 28

结论 29

致谢 32

参考文献 33