土豆灭茬机的设计(CATIA三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

土豆灭茬机的设计(CATIA三维图)(任务书,开题报告,论文说明书10000字,CATIA三维图)

摘要

土豆是当今人类社会的四大粮食作物之一,仅次于水稻、玉米和小麦。我国是世界上土豆生产大国,总产量居世界第一。土豆收获前需要对土豆进行灭茬工作,而我国传统土豆种植方式机械化水平很低,机械化灭茬普及率并不高。目前,市场上销售的灭茬机产品大部分仅适用于北方作业区,南方多为山地和梯田,并不适用。人工灭茬费时费力、劳动强度大,因此给广大农民造成极大的困扰。为了解决上述问题,本文就国内外各种灭茬机进行分析和参考,设计了一款适用于我国南方耕地的土豆灭茬机。该机功能与市面上的粉碎灭茬机有所不同,仅将土豆茬割断,并排入两旁的沟壑中,这样可以大大降低功耗,提高工作效率,使灭茬机更小巧轻便。本文首先对灭茬机的总体方案做出合理的选择,巧妙地采用后悬挂式微耕机倒退运行方式的配套形式,避免了压茬的问题。然后合理设计传动模式,采用一级锥齿轮减速变向传动,并就锥齿轮、轴等零件进行合理的参数计算。接着合理设计了机架、刀具、挡茬机构、清茬机构和罩壳等部分,机架和挡茬机构均采用空心方钢焊接而成,挡茬机构可以提高灭茬效率,有效避免土豆茬缠绕的情况,刀具采用活动刀片,可以有效降低折断的风险。最后对锥齿轮、轴和键等重要零件进行了参数计算和强度校核,对轴承和弹性挡圈等标准零件进行了合理的选择。

关键词:土豆,灭茬,设计

Abstract

In every human society. The potato is one of the four major food crops after rice, maize and wheat. Our country is the largest potato production country in the world. As everyone knows, we need to stubble on potato before harvest, but we still in traditional way of potato planting that the mechanization level and mechanization of stubble penetration rate are both low. At present, most of the stubble machine on the market only applies to working in the north, it’s not suitable for the south. Artificial stubble is a common way for the south. It needs large timeand labor force and takes a great trouble to all farmers. In order to solve the above problems, we took the various stubble machine at home and abroad for reference and designed a potato stubble machine that suitable for southern land of China. The function has a large different with those of stubble machine on market, It only cuts potato crop and puts into the gaps on the two sides. This way greatly reduces power consumption and improves the work efficiency. There are make a reasonable choice to overall scheme of the stubble machine in this article. we skillfully use after hanging tractor supporting form of reverse operation mode, to avoid the problem of the pressure of crop. It has a reasonable design at transmission mode such as level1 bevel gear be used in reducer to drive. There are a reasonable caculation in bevel gear, shaft and other parts of parameters. Then the frame, tool and stubble retaining mechanism, crop and cover parts are with reasonable design, such as frame and crop agency welded hollow square steel together. The crop institution could improve the efficiency of stubble and effectively avoid the potato crop of winding. The active cutter blades can reduce effectively the risk of fracture. In a world, We made a parameter calculation and strength check to bevel gear, shaft and key and a reasonble choice in the important parts of bearing and the elastic ring standard parts.

Key words:potato , stubble cleaning , design

土豆灭茬机的技术要求

国内土豆灭茬机械技术发展还处于起步阶段,但各类型机应满足一下技术要求:

(1) 灭茬率

要求灭茬幅宽80cm,灭茬高度1~5 cm,灭茬率应不低于95%。

(2) 清茬率

灭茬机必须有良好的清茬机构,能将土豆茬清除至两旁的沟里,便于之后收获机的作业,清除率应不低于95%。

(3) 生产效率

机械灭茬的目的在于减轻农民劳动强度,提高生产效率,适时灭茬。因此,灭茬机作业时应具有一定的作业速度,且能稳定作业。

(4) 其它要求

土豆灭茬机灭茬机构和清茬机构应协调工作,尽可能减少自身的动力损耗,保持作业稳定。

目录

摘要 I

Abstract II

1绪论 - 1 -

1.1土豆灭茬机研究的目的和意义 - 1 -

1.2土豆灭茬机的发展概况 - 1 -

1.2.1国内土豆灭茬机的发展概况 - 1 -

1.2.2国外土豆灭茬机的发展概况 - 3 -

1.3土豆灭茬机的类型及技术要求 - 5 -

1.3.1土豆灭茬机的类型 - 5 -

1.3.2土豆灭茬机的技术要求 - 5 -

1.4土豆灭茬机发展的主要制约因素 - 6 -

1.4.1种植形式和生产规模 - 6 -

1.4.2动力配套问题 - 6 -

1.4.3机械性能问题 - 6 -

2土豆灭茬机的总体方案设计 - 7 -

2.1总体结构方案的确定 - 7 -

2.1.1方案的提出 - 7 -

2.1.2方案的确定 - 9 -

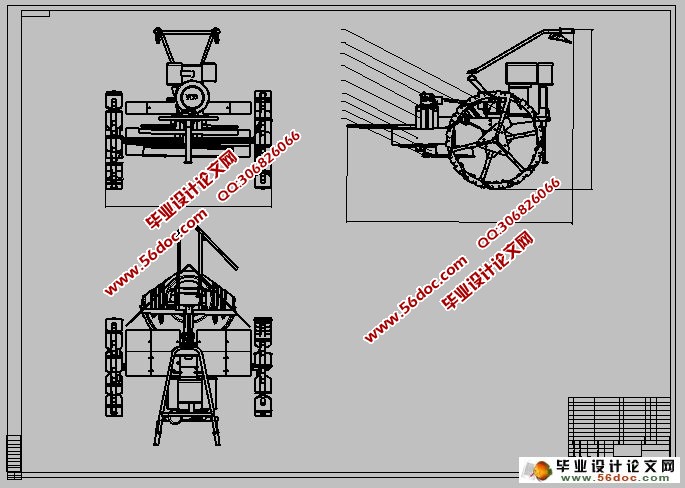

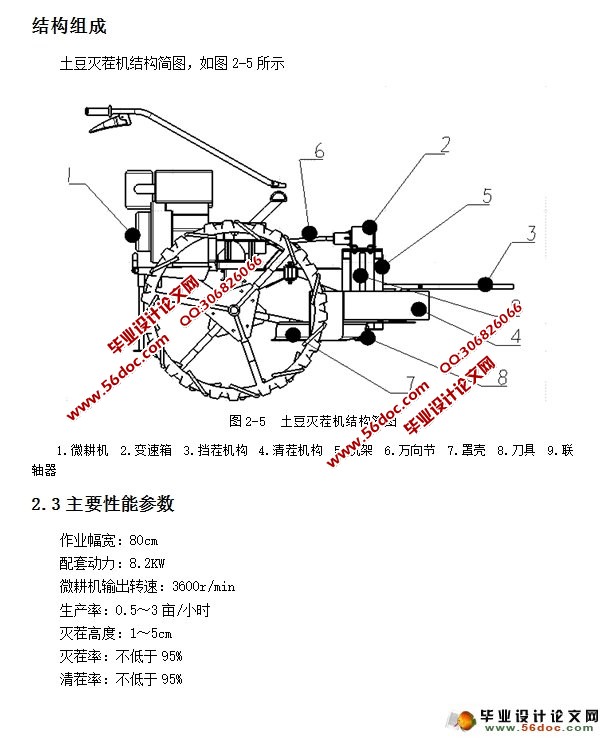

2.2结构组成 - 9 -

2.3主要性能参数 - 10 -

3主要部件的设计 - 11 -

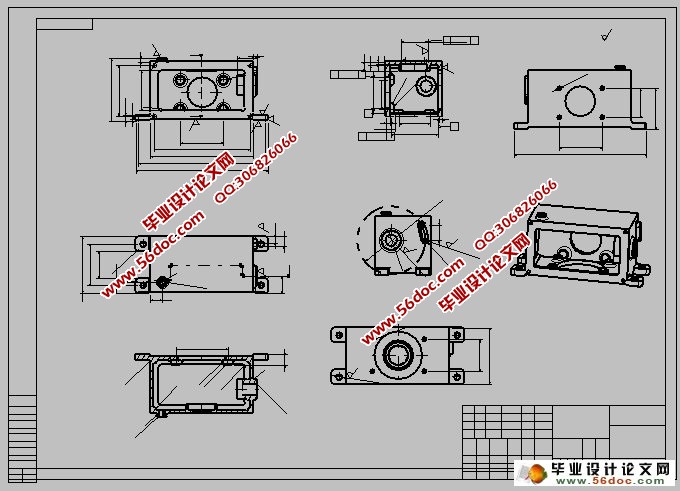

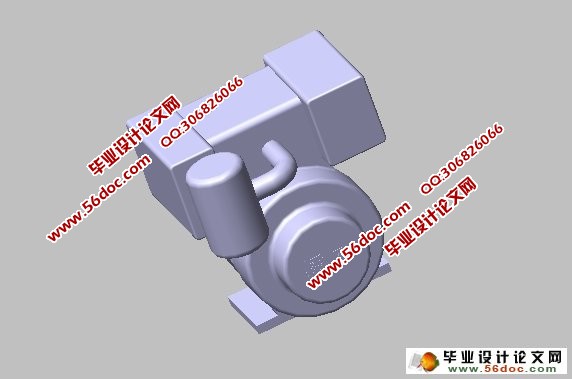

3.1传动部分的设计 - 11 -

3.1.1传动比的计算 - 11 -

3.1.2圆锥齿轮传动的设计 - 11 -

3.1.3轴的设计 - 13 -

3.2挡茬部分的设计 - 16 -

3.3刀具部分的设计 - 16 -

3.4清茬部分的设计 - 17 -

4主要零件的强度校核 - 18 -

4.1变速箱锥齿轮的强度校核 - 18 -

4.2轴的校核 - 18 -

4.2.1输入轴的校核 - 18 -

4.2.2输出轴的校核 - 19 -

4.3重要键的校核 - 19 -

5结论 - 21 -

参考文献 - 22 -

致谢 - 23 -