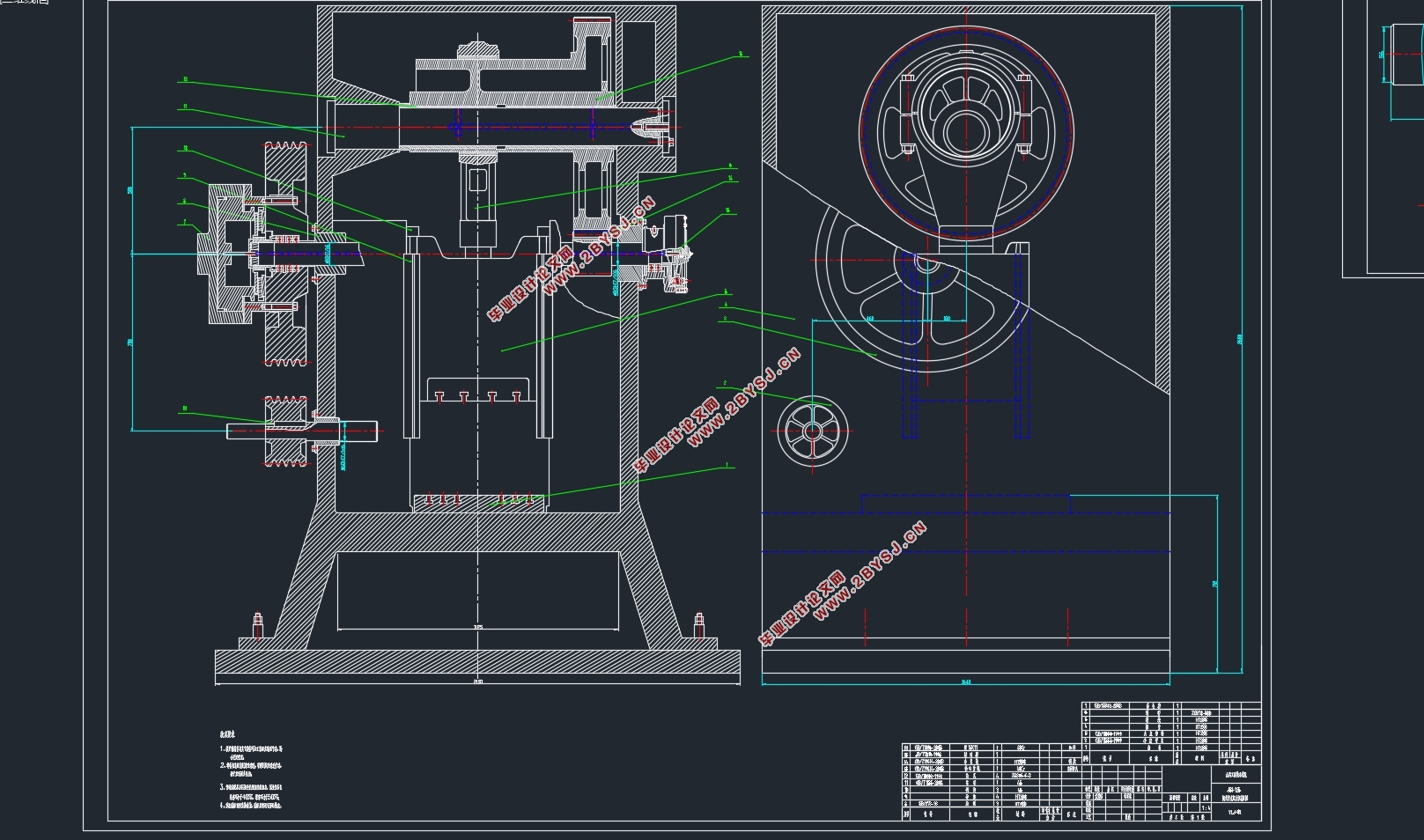

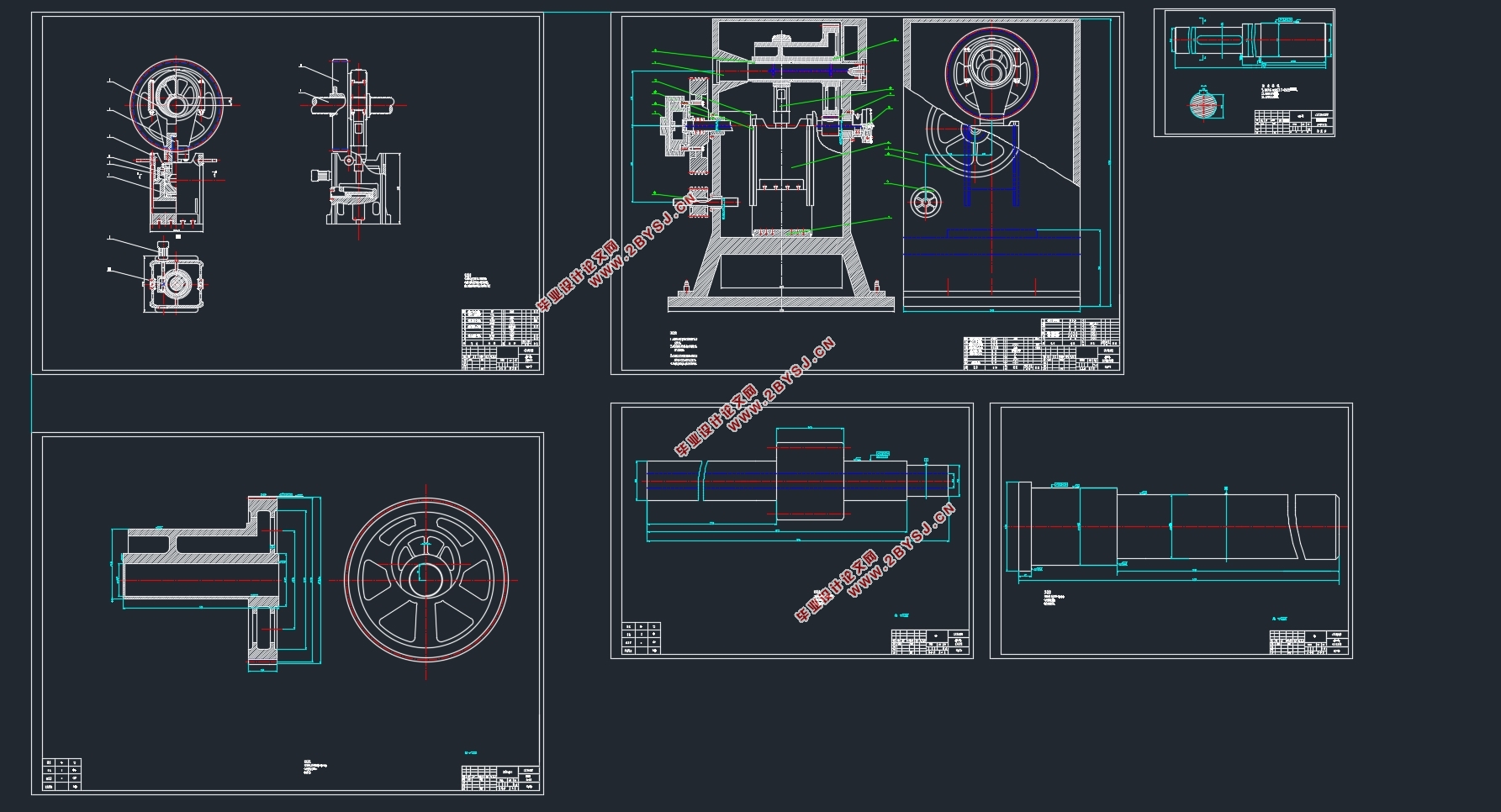

J31-125闭式单点曲柄压力机的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

J31-125闭式单点曲柄压力机的设计(含CAD零件图装配图)(论文说明书17000字,外文翻译,CAD图6张)

摘 要

制造业的发展是国家经济发展的重要保证,同时又是评判一个国家科技实力和国防实力是否领先的重要标准。在机械制造业中,锻压制造是目前全世界应用最为广泛的制造方法之一-。而在锻压机械中,曲柄压力机又占有很大的比重。曲柄压力机主要是通过飞轮将电机的能量存储,在工作的瞬间通过曲轴及与其相连的滑块对特定的模具做功而释放能量。如今,随着汽车工业的兴起,曲柄压力机以及其他锻压设备得到了迅速发展。众所周知,由于采用现代化的锻压工艺生产工件具有效率高,质量好,能量省和成本低的优点。所以,工业先进的国家越来越多地采用锻压工艺代替传统的切削工艺和其他工艺。近年来,机械压力机广泛应用于冲裁,落料,弯曲,折边,浅拉伸及其他冷冲压工序,是汽车,摩托车,家用电器,仪器仪表,轻工,国防工业,化工容器,电子等行业必备的关键设备。伴随着工业的发展,压力机的种类和数量越来越多,质量要求越来越大,能力越来越大,它在机械制造业和其它相关行业中的作用日趋显著。因此对压力机的精度和生产率等的要求也就越来越高,所以对压力机进行优化设计是十分必要的,对压力机的机身结构,传动系统,附属装置以及辅助系统等进行优化,生产出具有高效率,高精度,低成本,自动化等现代化制造特点的压力机,是值得研究和探讨的。

关键词:锻压制造;曲柄压力机;锻压工艺……

J31-125 Closed single point crank press

Abstract

The development of manufacturing industry is an important guarantee of national economic development, and it is also an important criterion for judging whether a country's scientific and technological strength and national defense strength are ahead. Forging manufacturing is one of the most widely used manufacturing methods in the world at present in the machinery manufacturing industry. In forging press, crank press occupies a large proportion. The crank press mainly stores the energy of the motor through the flywheel, and releases energy through the crankshaft and the slider connected to it at the moment of operation. Today, with the rise of the automotive industry, crank presses and other forging equipment have developed rapidly. It is well known that the modern forging process has the advantages of high efficiency, good quality, low energy saving and low cost. Therefore, more and more advanced industrial countries are using forging techniques instead of traditional cutting techniques and other techniques. In recent years, mechanical presses have been widely used in stamping, dressing, bending, folding, shallow stretching and other cold stamping processes. They are essential for automobiles, motorcycles, household appliances, instrumentation, light industry, national defense industry, chemical containers, and electronics. Key equipment. With the development of industry, there are more and more types and quantities of pressure machines, and more and more quality requirements and capabilities. Its role in machinery manufacturing and other related industries has become increasingly prominent. Therefore, the requirements for the accuracy and productivity of the press are also getting higher and higher. Therefore, it is very necessary to optimize the design of the press. The fuselage structure, transmission system, accessories, and auxiliary systems of the press are optimized. The production is highly efficient. High precision, low cost, automation and other modern manufacturing characteristics of the press, is worth studying and discussing.

Key words: Forging and compression manufacturing; Crank press; Forging process ...

目 录

摘 要 I

ABSTRACT II

1 曲柄压力机概述 1

1.1 曲柄压力机的构件以及工作原理 1

1. 2 J31-125压力机的主要技术参数 3

1.2.1 公称压力 3

1.2.2 滑块行程 3

1.2.3 滑块每分钟行程次数 3

1.2.4 装模高度 3

1.2.5 压力机工作台面尺寸及滑块底面尺寸 4

1.2.6 漏料孔尺寸 4

1.2.7 模柄孔尺寸 4

1.2.8 立柱间距离 5

2 J31-125压力机的方案对比和选择 7

2.1 电动机的选择 7

2. 2 计算总功 8

2.2.1 工作变形功A1 8

2.2.2 拉延垫工作功A2 8

2.2.3 工作行程时由于曲柄滑块机构的摩擦所消耗的能量A3 9

2.2.4 工作行程时由于压力机受力系统的弹性变形所消耗的能量A4 9

2.2.5 压力机空程向下和空程向上时所消耗的能量A5 10

2.2.6 滑块停顿飞轮空转时所消耗的能量A6 10

2.2.7 单次行程时,离合器接合所消耗的能量A7 11

2.3 传动系统的对比和设计 12

2.3.1 确定滑块上加力点的数目及机构的运动分析 13

2.3.2 确定传动系统的布置方式 16

2.3.3 确定传动级数和各传动比的分配 17

2.3.4 选择离合器和制动器的类型 18

3 主要零件的设计与校核 23

3.1 V带和带轮设计 23

3.1.1 确定计算功率Pca 23

3.1.2 选取窄V带带型 23

3.1.3 确定带轮基准直径 23

3.1.4 确定窄V带的基准直径和传动中心距 23

3.1.5 验算主动轮上的包角α1 24

3.1.6 计算窄V带的根数z 24

3.1.7 计算预紧力 24

3.1.8 计算作用在轴上的压轴力 25

3.2 齿轮的设计 25

3.2.1 概述 25

3.2.2 传动齿轮的设计 26

3.3 轴的设计 30

3.3.1 大皮带轮轴的设计 30

3.3.2 偏心齿轮轴的设计 32

3.4 滑块与导轨的设计 35

3.5 连杆的设计 36

3.5.1 连杆及装模高度调节机构 36

3.5.2 连杆及调节螺杆的强度校核 36

3.5.3 滑动轴承的校核 37

4 机身的设计 39

4.1 机身的比较和选择 39

4.2 机身的强度计算 40

4.2.1 立柱和拉紧螺栓强度校核 40

5 辅助装置的选择 45

5.1 过载保护装置的选择 45

5.2 拉延垫 45

5.3 滑块平衡装置 45

5.4 润滑系统 46

总结 49

附录 50

参考文献 51

外文文献 52

中文翻译 62