高炉冷却壁水管密封环焊接机器人工作站设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

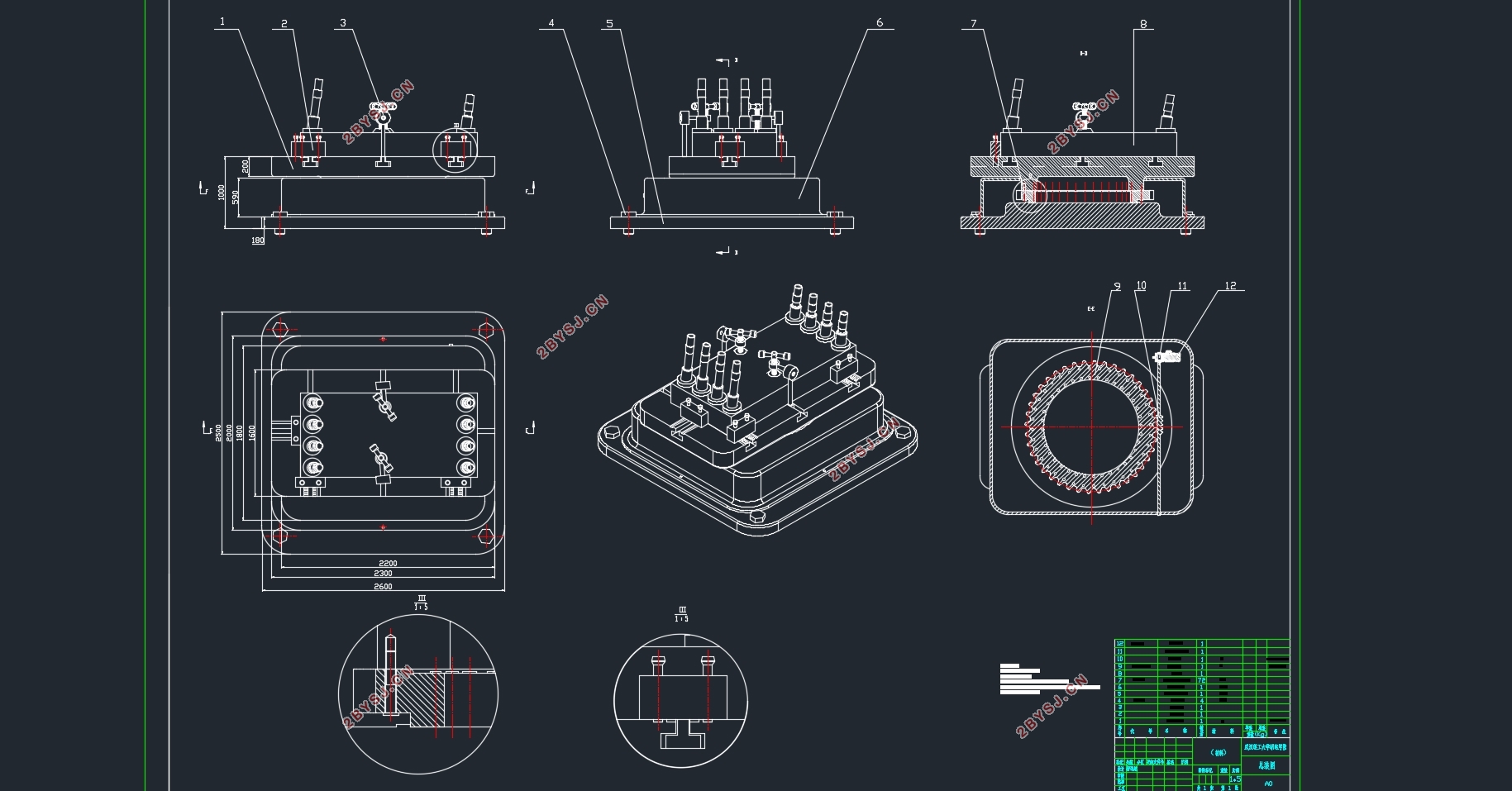

高炉冷却壁水管密封环焊接机器人工作站设计(含CAD零件图装配图)(任务书,开题报告,论文说明书22000字,CAD图7张)

摘要

冷却壁是高炉上重要的水冷件,作为消耗品安装在高炉上,需要不断更换,这就使得冷却壁需要不断的大批量生产。在冷却壁的生产制造过程中,水管和套管间的密封焊接作为一个比较重要的工序,占冷却壁生产周期比重大。但是,目前国内外冷却壁的焊接普遍采用手工电弧焊工艺。每块冷却壁上有8根水管,共16条环焊缝。由于焊缝较多、冷却壁数量大,使得焊接工作量大。另外,手工焊接存在焊接质量稳定性差、生产效率低、工人劳动强度高及工作环境恶劣等弊端。因此,本文设计提出了一套基于标准6轴焊接机器人的自动化焊接工作站的方案。主要研究内容如下:

(1)对冷却壁水管密封环传统手工电弧焊工艺研究分析,确定了冷却壁水管及套管的焊接接头形式、焊接顺序及焊缝质量要求。

(2)对冷却壁焊接自动化进行可行性分析,提出使用机器人工作站进行自动化焊接的总体方案,并详细分析给出了机器人工作站中机器人、控制器系统、焊接电源、焊枪、软件系统等选型,完成总体方案设计并进行技术经济分析,得出该方案经济可行。

(3)根据需要设计了一种单轴水平回转变位机以及冷却壁的工装夹具,变位机采用模块化设计的思路,驱动和承力分离,不仅能延长变位机寿命,也方便后续的更换及维修;夹具结构简单、夹持方便可靠,利于缩短装夹时间,提高生产效率。

(4)对机器人进行了路径规划、焊接工艺参数确定及示教编程,并通过RobotStudio系统仿真软件对机器人开展了模拟仿真试验,对机器人进行了虚拟轨迹规划及碰撞检测,模拟仿真试验结果表明,所规划的路径可行,一台机器人同变位机的协作动作工作站方案可行。

(5)对冷却壁铸造毛坯误差就行分析,为保证焊缝质量要求,提出采用一种基于电弧信号的弧焊跟踪技术方案,详细给出了电弧传感器模型及原理分析、焊接电流的采集方法及分析、理论偏差的提取及电弧传感器偏差补偿方案。此方案成本低、易实现且能满足冷却壁密封环焊缝的跟踪要求。

关键词:机器人工作站;示教仿真;焊接工艺;变位机;焊缝跟踪

Abstract

The stave is an important water-cooled part of the blast furnace, which is installed on the blast furnace as a consumable product and needs to be continuously replaced. This results in constant mass production of the stave. In the manufacturing process of the stave, the sealing welding between the water pipe and the casing is a relatively important process, which occupies a significant proportion of the production cycle of the stave. However, the manual arc welding process is commonly used for the welding of cooling walls at home and abroad. There are 8 water pipes on each stave, with a total of 16 girth welds. Due to the large number of welds and the large number of cooling walls, the amount of welding work is large. In addition, manual welding has disadvantages such as poor welding quality stability, low production efficiency, high labor intensity of workers, and poor working environment. Therefore, this paper designs and proposes a set of automated welding workstations based on standard 6-axis welding robots. The main research content is as follows:

(1) Research and analysis of the traditional manual arc welding process for the cooling wall water pipe seal ring, and the welding joint form, welding sequence and weld seam quality requirements for the cooling wall water pipe and casing are determined.

(2) Feasibility analysis of the automation of stave welding is proposed, an overall plan for automatic welding using a robot workstation is proposed, and the selection of robots, controller systems, welding power supplies, welding guns, and software systems in the robot workstation are given in detail. Completion of the overall program design and technical and economic analysis have led to the conclusion that the program is economically viable.

(3) According to the needs of the design of a single-axis horizontal return conversion machine and cooling wall fixture, the use of modular design ideas, drive and bearing separation, not only can extend the life of the positioner, but also to facilitate follow-up the replacement and maintenance of the fixtures are simple in structure, convenient and reliable in clamping, which helps shorten the installation time and improve the production efficiency.

(4) Path planning, welding process parameter determination and teaching programming of the robot were performed. Robot Simulation software was performed by RobotStudio system simulation software. The virtual trajectory planning and collision detection were performed on the robot. The simulation results show that the planned path is feasible and a collaborative action workstation scheme for a robot with the positioner is feasible.

(5) Analyze the cooling slab casting blank error. In order to guarantee the quality requirements of the welding seam, an arc welding tracking technology scheme based on arc signal is proposed. The arc sensor model and principle analysis, welding current acquisition method are given in detail. Analysis, theoretical deviation extraction and arc sensor offset compensation scheme. This solution is low-cost, easy to implement, and can meet the tracking requirements for cooling wall seal ring welds.

Key Words:robotic workstation;teaching simulation; welding process; positioner; weld seam tracking

目录

摘要 I

Abstract II

第1章绪论 1

1.1研究目的及意义 1

1.2国内外研究现状 2

1.2.1我国冷却壁生产制造现状 2

1.2.2国外冷却壁生产制造现状 3

1.3主要研究内容 4

第2章冷却壁密封环焊接工艺分析 5

2.1冷却壁水管及套管密封环的焊接方法 5

2.2冷却壁水管及套管密封环的焊接接头形式 6

2.3冷却壁水管及套管密封环焊接工艺评定 8

2.3.1焊接工艺制作和检验标准 9

2.3.2手工电弧焊焊接工艺参数 9

2.3.3焊接步骤 9

2.4本章小结 10

第3章冷却壁焊接机器人工作站总体设计 11

3.1冷却壁焊接自动化可行性分析 11

3.2机器人工作站设计选型 13

3.2.1机器人系统选型 13

3.2.2机器人焊接电源 16

3.2.3机器人焊枪 16

3.2.4供气系统 17

3.2.5安全装置 17

3.3焊接机器人总体布局 18

3.4焊接机器人的技术经济分析 19

3.5本章小结 20

第4章单轴变位机及冷却壁工装夹具设计与建模 21

4.1单轴水平回转变位机的设计 21

4.1.1变位机的整体方案设计 21

4.1.2回转机构设计 22

4.1.3第一级蜗杆的设计 22

4.1.4第二级蜗轮的设计蜗杆 24

4.1.5回转支承选型及分析 27

4.2冷却壁工装夹具设计 28

4.3建模 29

4.3.1冷却壁建模 29

4.3.2单轴水平回转变位机的建模 30

4.3.3冷却壁夹具建模 31

4.4本章小结 32

第5章机器人轨迹规划及仿真 33

5.1机器人示教编程 33

5.1.1示教过程 33

5.1.2冷却壁示教轨迹规划 34

5.2机器人焊接工艺参数 35

5.3 冷却壁环焊缝轨迹示教 37

5.3.1圆弧轨迹示教 37

5.3.2圆弧摆动轨迹示教 37

5.4工作站模拟仿真 38

5.4.1机器人路径规划 38

5.4.2碰撞检测 40

5.5焊缝轨迹跟踪及误差补偿 41

5.5.1冷却壁铸造毛坯误差分析及焊接解决方案 41

5.5.2电弧静态模型 42

5.5.3电弧传感器偏差补偿方案 44

5.6本章小结 45

第6章结论及展望 46

6.1结论 46

6.2展望 47

参考文献 48

附录 49

致谢 50