三跨68m+120m+68m西河大桥上部结构设计与计算分析(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

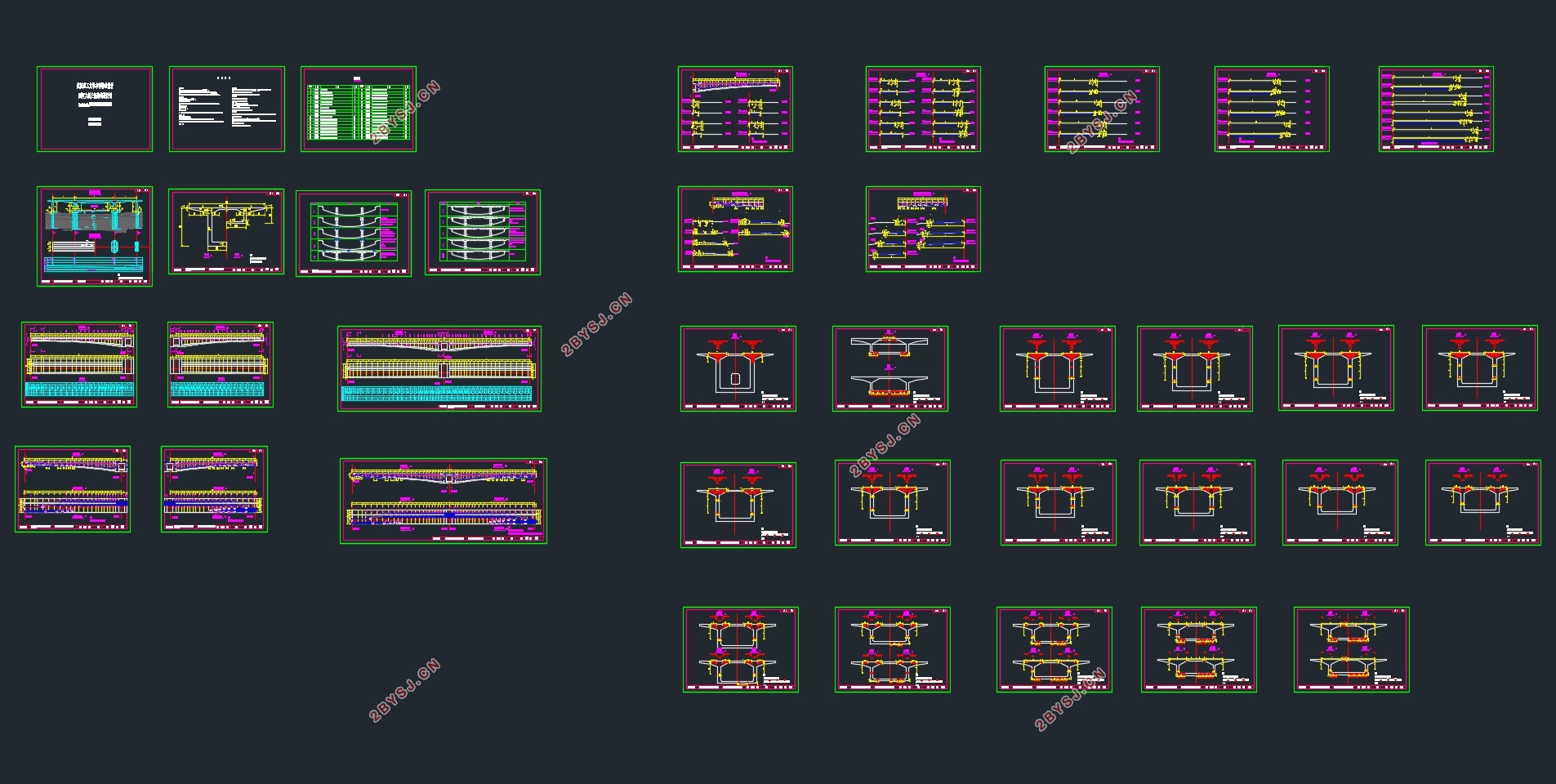

三跨68m+120m+68m西河大桥上部结构设计与计算分析(含CAD图)(任务书,开题报告,论文计算书19000字,CAD图34张)

摘 要

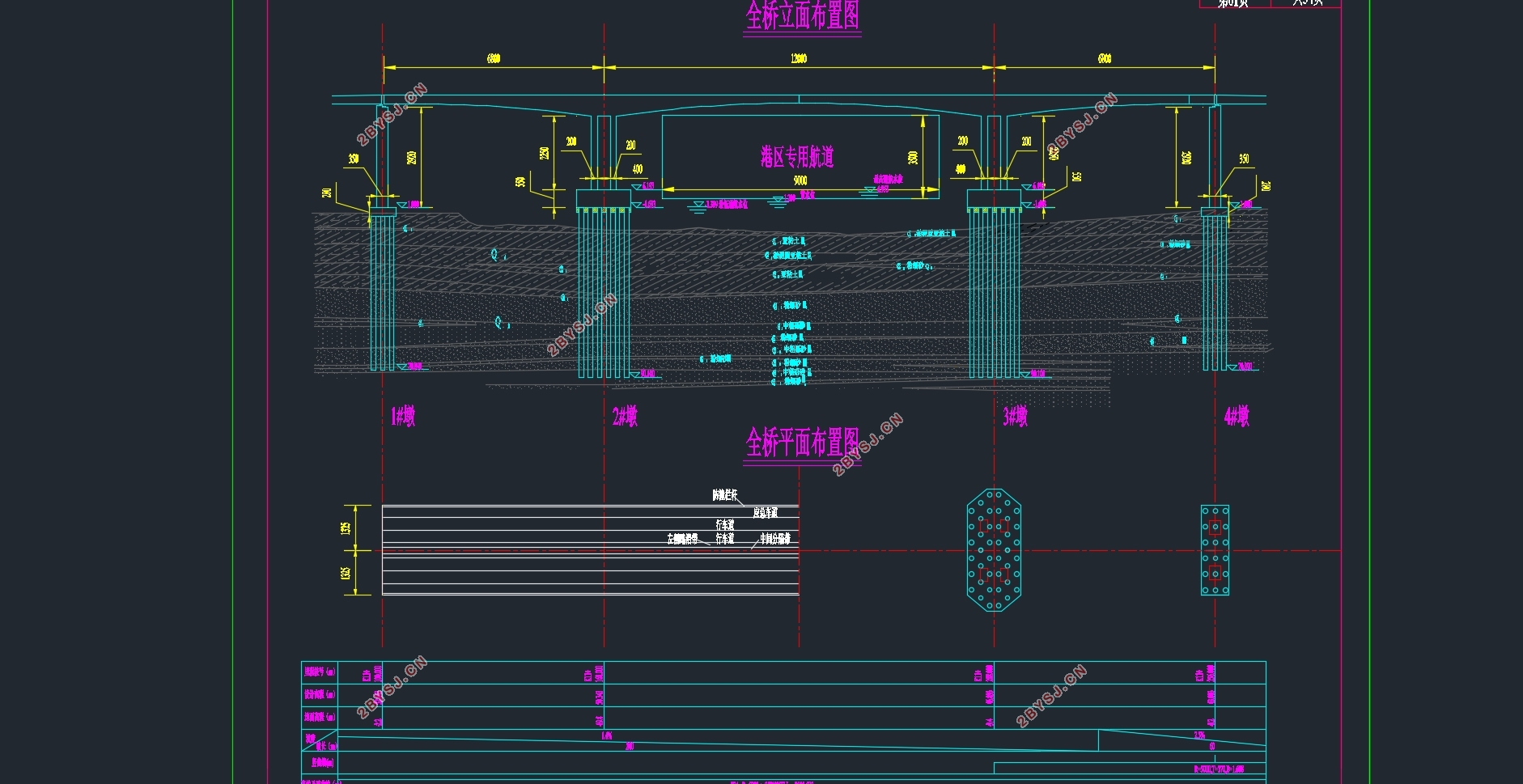

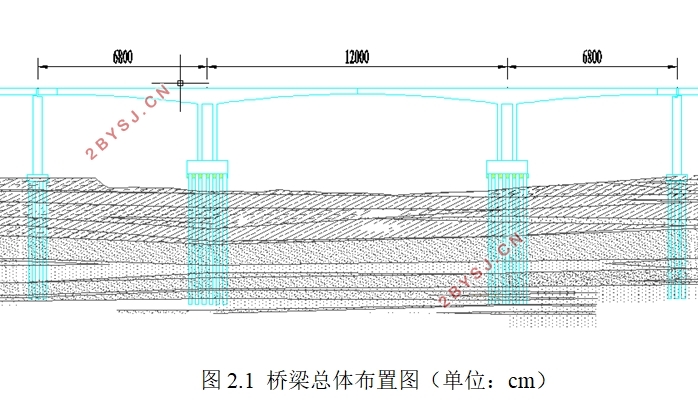

本设计为预应力混凝土连续刚构桥,全长为256m,由三跨68m+120m+68m构成,截面形式采用箱型截面(单箱单室),设计荷载标准为公路-I级荷载,主梁施工采用挂篮法悬臂对称施工。本文未进行下部结构(桥墩、承台和桩基)、横向预应力及竖向预应力的设计,重点完成上部结构的设计与计算分析。

连续刚构桥优点很多,不仅保留了连续梁桥的特点,还有很多连续梁桥不可比拟的特点,如跨越能力大,墩梁固结体系,刚度大,变形小,双薄壁墩节省支座数量,优化了结构的受力性能等。

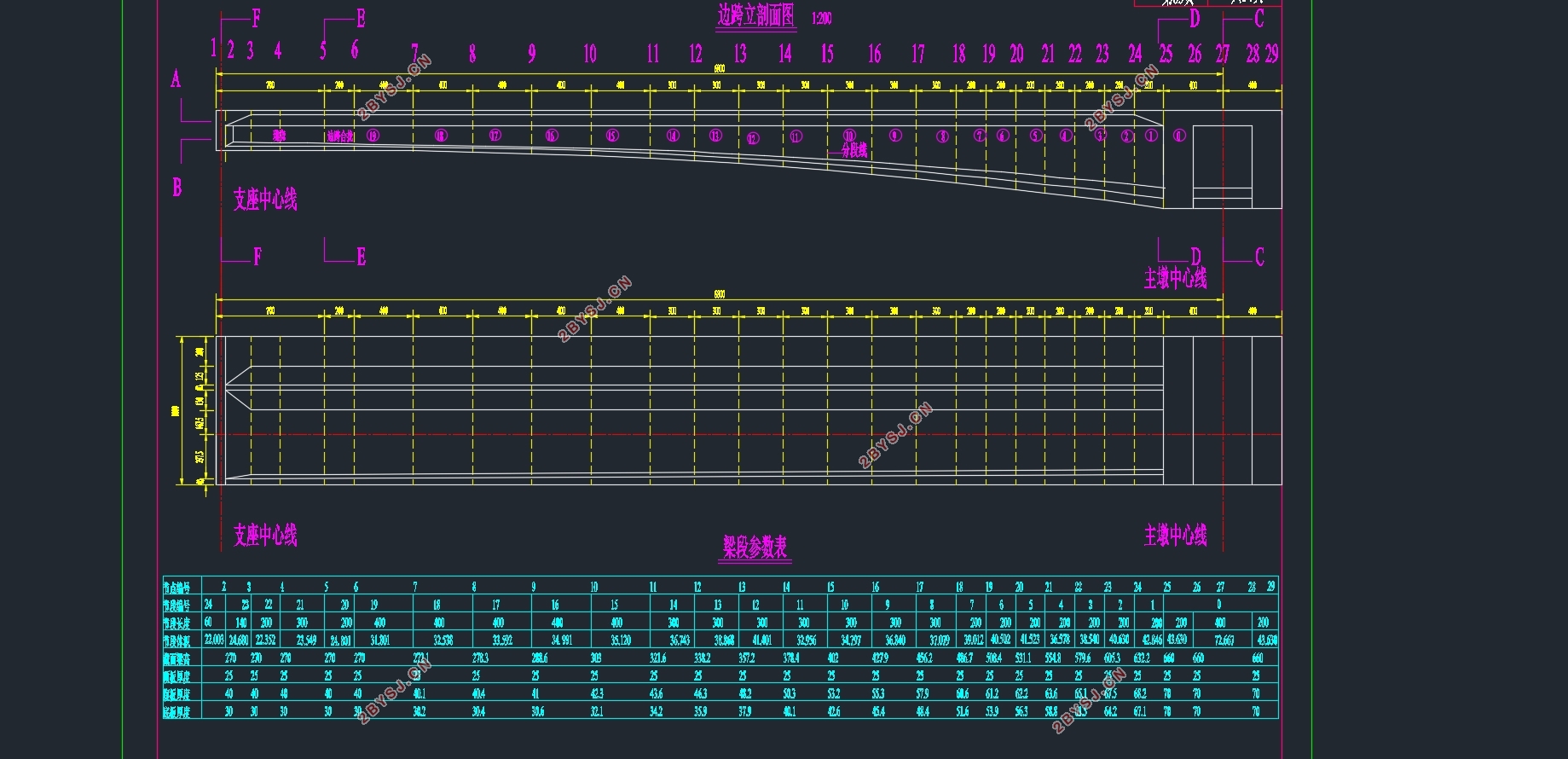

在进行设计的时候,借鉴了比较多的工程实例,也参考了大量的文献资料,对结构受力方面进行了比较详细的分析和研究。采用MIDAS/Civil软件建立桥梁模型,截面采用单箱单室截面,主梁截面高度采用二次抛物线变化,从中支点处最大6.7m到跨中最小2.7m,顶板厚度均为25cm。为了减小施工难度,并结合连续刚构桥的受力特点,底板厚度呈直线线性变化,由中支点向跨中减小,从中支点处为最大0.7m到跨中最小为0.3m。腹板厚度也是直线线性变化,由中支点向跨中减小,从中支点处为最大0.7m到跨中最小为0.4m。建好模型后,首先运用MIDAS/Civil软件对模型进行详细内力分析,然后估算预应力钢束数量,再配置预应力钢束,最后验算控制截面的承载能力和性能状态。完成内力分析后,先进行绘制纵向预应力断面图、预应力布置图、主桥桥跨布置图、主桥指导性施工步骤图、预应力钢束大样图等,然后进行外文翻译,最后编辑设计计算说明书和文档整理。

关键词: 预应力混凝土连续刚构桥;悬臂施工;内力分析。

Abstract

The design of the prestressed concrete continuous rigid frame bridge, a total length of 256m, by the three-span (68m +120m +68 m) composition, cross-section of the box-type cross-section (single-box single room), designed load-based highway-I load Construction of cantilever symmetry with cantilever construction in beam construction. In this paper, no design of the lower structure (piers, cap and pile foundation), transverse prestressing and vertical prestressing is carried out, and the design and calculation of the superstructure are mainly completed.

There are many advantages of continuous rigid bridge, which not only retains the characteristics of continuous beam bridge, but also has many unmatched characteristics of continuous beam bridge, such as the ability of crossing, the consolidation system of pier and beam, the stiffness is big, the deformation is small, The number of seats, optimize the structure of the force performance.

In the design of the time, drawing on the more examples of engineering, but also refer to a large number of literature, the structure of the force carried out a more detailed analysis and research. The bridge model was established by using MIDAS / Civil software. The cross section of single section was adopted. The height of the main section was double parabola, and the maximum distance was 6.7m from the fulcrum to the minimum of 2.7m and the thickness of the roof was 25cm. In order to reduce the difficulty of construction, combined with the characteristics of the continuous rigid frame bridge, the thickness of the bottom plate is linearly changed from the middle fulcrum to the mid-span, from the maximum point of 0.7m to the minimum of 0.3m.After the model is built, the detailed internal force analysis of the model is carried out by using MIDAS / Civil software. Then, the number of prestressed steel beams is estimated and the prestressed steel beam is arranged. Finally, the bearing capacity and performance status of the control section are checked.After the internal force analysis is completed, the longitudinal prestressing section diagram, the prestressed layout diagram, the main bridge bridge cross-layout diagram, the main bridge guiding construction step diagram, the prestressed steel beam large sample map, etc., and then the foreign translation, the final editing Design calculations and documentation.

Key words: prestressing concrete continuins frame bridge; cantilever construction;analysis of internal forces.

目录

第1章 绪论 1

1.1连续刚构桥的发展 1

1.1.1国外发展 1

1.1.2国内发展 1

1.2桥型方案比选 2

1.2.1桥梁设计的基本条件 2

1.2.2方案比选 2

第2章 桥梁总体布置及截面尺寸拟定 4

2.1设计依据及基本资料 4

2.1.1主要技术指标 4

2.1.2主要材料 4

2.2桥梁总体布置 4

2.3截面尺寸拟定 5

2.3.1桥梁截面高度 5

2.3.2腹板厚度 6

2.3.3顶板厚度 6

2.3.4底板厚度 6

2.3.5中支点和跨中截面布置 6

第3章 桥梁模型的建立 8

3.1概述 8

3.2建立模型 9

3.2.1梁节段的划分 9

3.2.2材料规格 10

3.2.3箱梁截面的定义以及桥梁边界条件的添加 11

3.2.4静力荷载的添加 12

3.2.5施工阶段的定义 13

3.2.6完成模型 14

第4章 桥梁结构内力计算 15

4.1桥梁恒载内力计算 15

4.1.1计算阶段划分 15

4.1.2施工阶段内力计算 15

4.1.3成桥阶段内力计算 18

4.2桥梁活载内力计算 19

4.3支座沉降内力计算 21

4.3.1模型设置 21

4.3.2计算结果 22

4.4温度变化内力计算 23

4.4.1模型设置 23

4.4.2计算结果 23

第5章 预应力钢筋设计 25

5.1纵向预应力筋估算 25

5.1.1计算原理 25

5.1.2 纵向预应力束的估算 27

5.2纵向预应力钢束的布置 29

5.3预应力损失及有效预应力计算 31

5.3.1概述 31

5.3.2电算结果 31

第6章 次内力计算及内力组合 34

6.1预应力次内力计算 34

6.1.1概述 34

6.1.2先期预应力徐变次内力 34

6.1.3后期合拢预应力弹性次内力 35

6.2 徐变次内力计算 36

6.2.1混凝土徐变理论 36

6.2.2徐变次内力计算方法 36

6.2.3徐变次内力计算结果 37

6.3温度次内力计算 37

6.3.1温度次内力的计算方法 37

6.3.2温度次内力的计算结果 40

6.4支座沉降次内力计算 40

6.4.1支座沉降次内力的计算方法 40

6.4.2支座沉降次内力的计算结果 40

6.5荷载组合 41

6.5.1作用分类和作用效应 41

6.5.2按承载能力极限状态组合 41

6.5.3按正常使用极限状态组合 42

第7章 截面验算 47

7.1正截面抗弯承载能力验算 47

7.2斜截面抗剪承载力验算 48

7.3施工阶段法向应力验算 48

7.4受拉区钢筋的拉应力验算 49

7.5使用阶段正截面压应力验算 52

7.6正截面抗裂性验算 53

7.7挠度验算 54

第8章 主要工程数量 56

8.1梁体混凝土用量 56

8.2钢束用量估算 57

8.3锚具用量估算 58

结论 61

参考文献 62

致谢 63