高粱秸秆剪切实验装置设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

高粱秸秆剪切实验装置设计(含CAD图)(任务书,论文说明书12000字,CAD图纸6张)

摘要

高粱在北方拥有非常好的经济效益和家庭效益而被十分重视,然而高粱种植普遍在农村,但高粱的秸秆在农村以直接焚烧或者就是烧锅煮饭炒菜了。虽然国内提倡努力发展农村沼气,让它发酵。但发酵时间过于漫长,而高粱的需求量很大在农村植种随即广泛,根本上用于沼气的高粱秸秆微乎其微;然而别的处理方式:如喂养家畜,取暖等,需求量也不大,对秸秆的处理也无济于事。倘若直接集中燃烧,那可能会直接引发出好多环境污染甚至可能会引发大型火灾,所以当前如何处理高粱秸秆使之还田覆盖技术能使原有保持的农业循环有利发展也能很好地解决好高粱秸秆的出处迫在眉睫。因此本文研究的高粱秸秆的切割性能参数和实验装置设计。

国内研究秸秆的覆盖还田技术比较短。其中国内科研人员像张彦河对高粱秸秆进行了径向剪切和轴向剪切实验,吴子岳等人自行通过研究高粱秸秆在秸秆前后无支撑力的条件下切断速度和耗费功率的切碎实验等等。但我国的高粱秸秆切割实验台是根据实验要求而研究的。然而国外,特别是欧美发达国家是率先提出还田覆盖技术,所以有关还田机器研究较早,现在他们一次就能对高粱秸秆收获和秸秆粉碎,在这方面研究及应用,我们应积极学习国外技术并能够有创新。

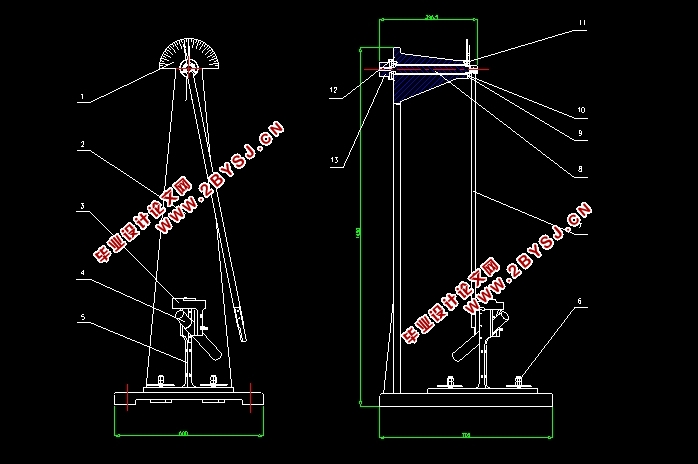

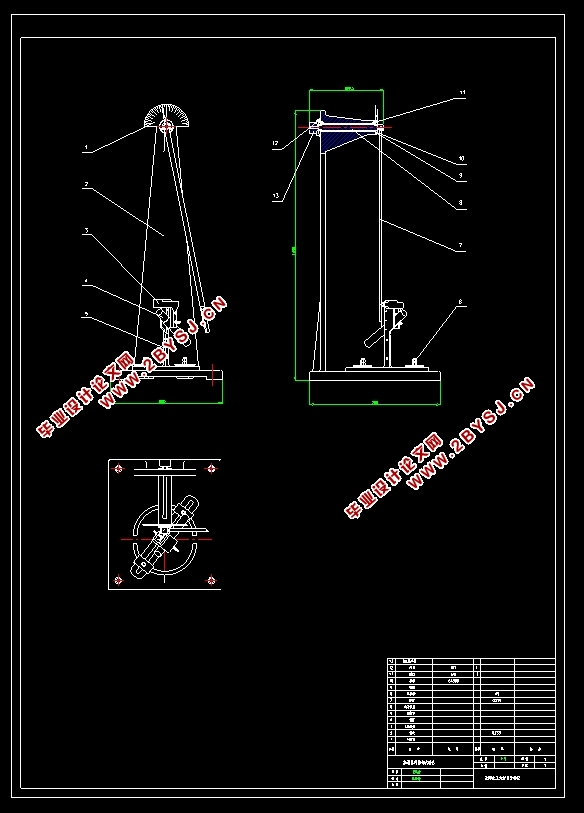

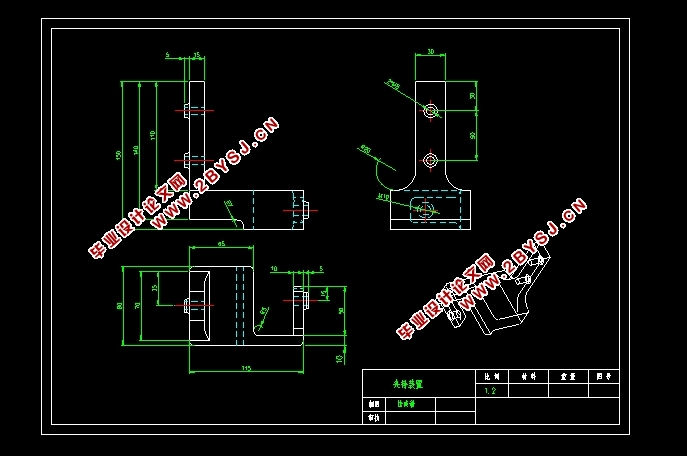

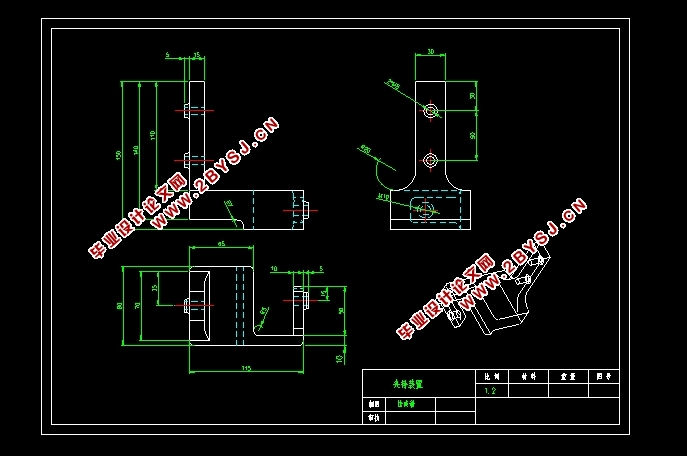

此次设计的高粱秸秆剪切实验台对高粱秸秆剪切特性研究为主,切割方向有斜切、砍切、和滑切。了解到切割方式从而设计出实验台路线又考虑到场地和设备的有限,以摆切式实验台为例调试出实验台参数。随后就着手准备机械系统的结构设计。首先设计出摆杆并计算出速度并验算,随后设计机架和转动轴及轴承,最后设计出调整架及夹持装置。摆杆及调整架校核,运用Pro/MECHANICA并分析应力和校核结果。测量系统是对实验台过程中的摆角、切割力和切割速度分为电测量和机械测量。切割力测量的设计首先了解它的测量原理并设计出传感器并计算出它。切割速度测量设计要了解光电编码器工作原理和光电编码器的选用。

本文设计的高粱秸秆剪切实验装置能达到最初设计的要求及相关参数。切割速度能达到7.6m/s,斜切角调整范围位 ,最大切割间隙为150mm。由有限元件校核分析重要零件,能够使实验台的强度和稳定性达到实际工作要求。此次设计的测量系统主要以电测量为主,机械测量为辅,使测量精度大大提高,这样测量对数据的采集和后期分析计算十分方便,可以成为高粱秸秆剪切实验装置的设计并完成相关实验。

关键词: 机械系统; 切割; 测量系统

Abstract

Sorghum has a very good economic and family benefits in the north is very seriously, but widespread planting of sorghum in rural areas, but in rural sorghum straw directly burning or cooking is cooking a pot roast. Although the domestic efforts to promote the development of rural marsh gas, let it ferment. But the fermentation time is too long, and a great demand sorghum planting seed in the countryside immediately widespread biogas sorghum stalks minimal for fundamental; however, other treatments: such as feeding livestock, and heating demand is not large, Straw treatment did not help. If direct centralized combustion, that could directly lead to a lot of environmental pollution and may even lead to a large fire, so how to deal with the current sorghum field covered so as to further favorable development of agricultural recycling technology allows to keep the original can be well solved Sorghum provenance imminent. Therefore, this paper is cutting performance parameters and test equipment design sorghum straw.

Domestic research straw mulching technology is relatively short. Which domestic researchers like Zhang Yan He sorghum straw radial and axial shear test shear, Wu Zi Yue themselves and others through research sorghum cutting speed and power consumption of chopped straw before and after the experiment at no supporting force conditions, etc. . However, China's sorghum cutting bench is based on the experimental requirements and research. But abroad, particularly in Europe and developed countries to field first proposed covering technology, now they will be able to once harvested sorghum stalks and straw crushed and applied research in this area,

we should actively learn foreign technology and to have innovati Cut the stalks of sorghum bench design research sorghum shear properties of the main direction of miter cut, slash, and sliding cut. Cutting learned way to design a bench routes and taking into account the limited space and equipment to put Case-cut bench debug the bench parameters. Then we begin to prepare the mechanical system design. First designed pendulum and calculate the speed and checking, then design the rack and the rotating shaft and the bearing, the final design of the frame and adjust the clamping device. Check and adjust the pendulum frame, usingPro / MECHANICA and analyze stress and check the results. Measurement system is a bench during the swing angle, cutting force and cutting speed into electrical measurement and mechanical measurements. Cutting force measurement design to first understand its measuring principle and sensor design and calculate it. Cutting speed measurement designed to understand the working principle of optical encoders and optical encoder selection.

Sorghum shear test apparatus designed in this paper can achieve the original design requirements and associated parameters. Cutting speed can reach 7.6m / s, the miter angle adjustment range position, the maximum cutting gap is 150mm. Checking by the finite element analysis of the important parts, enabling bench strength and stability to achieve actual work requirements. The design of the measuring system is mainly based electrical measurements,mechanical measurements, supplemented by the measurement accuracy is improved greatly, so that the measurement data acquisition and post analysis and calculation is very convenient, it can become a design sorghum shear test apparatus and complete the relevant Experimet.

Keyword: Mechanical Systems; cutting; measuringsy

秸秆切割试验台研究高粱秸秆的剪切性能为主,先后完成了切割速度,切割角高粱秸杆度,切割间隙和无底刃切割效果测试的功能,由于设计和测试台所需要的动态测试设备,完成了力量、速度、角度,做工作的测量。

2.1 试验台设计要求

高粱切割工艺和切割器,高粱物理和机械性能,绞吸和刀具在所有的速度的相对位置的属性有着密切的关系。用高粱的切割过程的物理和机械性能包括:切削切削阻力,耐弯曲性和耐断裂性,弹性模量和摩擦系数,用高粱样品,成熟度和很宽的湿度范围内变化的这些功能。切割方式主要是指刀具的方向进料,其中主要包括以下二个

(1)砍切,也叫正切,刀刃切割面和切割方向均与秸秆轴线方向垂直,如(a);(2)滑切刀刃切割面和切割方向均与秸秆轴线不垂直,二者之间有一角,该角为滑切角α,如图(b);斜切,刀刃切割面与秸秆轴线不垂直,二者之间有一夹角,但切割方向与秸秆轴线的水平投影相垂直,该角为斜切角β,如图 (c)。

秸秆削减现有的实验台主要是研究削减,削减主要的下滑大量的实验研究表明滑动削减的切割刀具切削时相同的材料相同的材料深度,减少滑量越大,即下摆裁成圆角的滑大的力量要求降低较小。以便它可以执行不同的动叶片和底部边缘切割冲击试验经验,以及切削角、切削速度的冲击试验。而在滑板上削减和斜十字测试。

2.2 试验台设计路线

分为机械系统的设计和测试床的设计,测试系统的设计以两个阶段,主要的机械系统设计要进行各部分的设计和检查;主要测试系统的测试值设计的基础上设计的,采用电阻应变计和光电编码器测量。

目录

第一章绪论 1

1.1 问题的提出 1

1.2 国内外研究现状 2

1.2.1 国内研究现状 2

1.2.2 国外研究现状 3

第二章总体方案设计 5

2.1 试验台设计要求 5

2.2 试验台设计路线 6

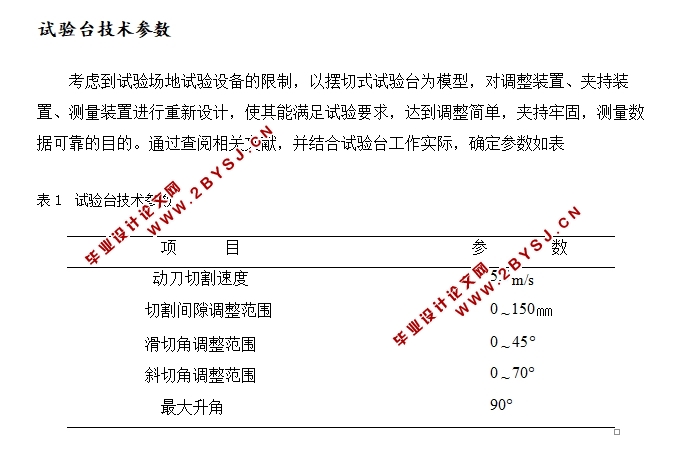

2.3 试验台技术参数 6

第三章机械系统设计及校核 8

3.1 结构设计 8

3.1.1 摆杆设计及速度验算 8

3.1.2 机架设计 10

3.1.3 转动轴及轴承设计 11

3.2 调整架及夹持装置设计 12

3.3 摆杆及调整架校核 13

3.3.1 使用Pro/MECHANICA的一般过程 13

3.3.2 应力分析 14

3.3.3 校核结果 19

第四章测量系统设计 20

4.1 切割力测量设计 20

4.1.1 切割力测量原理 20

4.1.2 传感器的设计与计算 21

4.2 切割速度测量设计 23

4.2.1 光电编码器工作原理 23

4.2.2 光电编码器的选用 25

第五章结论 28

参考文献 29

致谢 30